Industry information

Company News

- Aluminum veneer customization: the art of creating personalized spaces

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the latest fashion trend in the construction industry, revealing its charm!

- Aluminum veneer: the fashionable outerwear of modern architecture

- Fluorocarbon aluminum veneer: the new favorite of architecture, the perfect combination of fashion and practicality

Industry dynamics

- Aluminum veneer customization, creating exclusive space aesthetics

- The secret of aluminum veneer: it's not just a decoration for modern architecture

- Analysis of Types and Characteristics of Aluminum Veneers

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer shapes modern architectural style

Frequently asked questions

- Can the insulation function of aluminum veneer be long-lasting and effective?

- Is the use of aluminum veneer limited by geographical environment?

- What is the thermal insulation performance of aluminum veneer?

- Is there a wide range of color options for aluminum veneer?

- How sustainable is aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and technology of hyperbolic baking paint aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 25, 2025 19:24:05

- Click:0

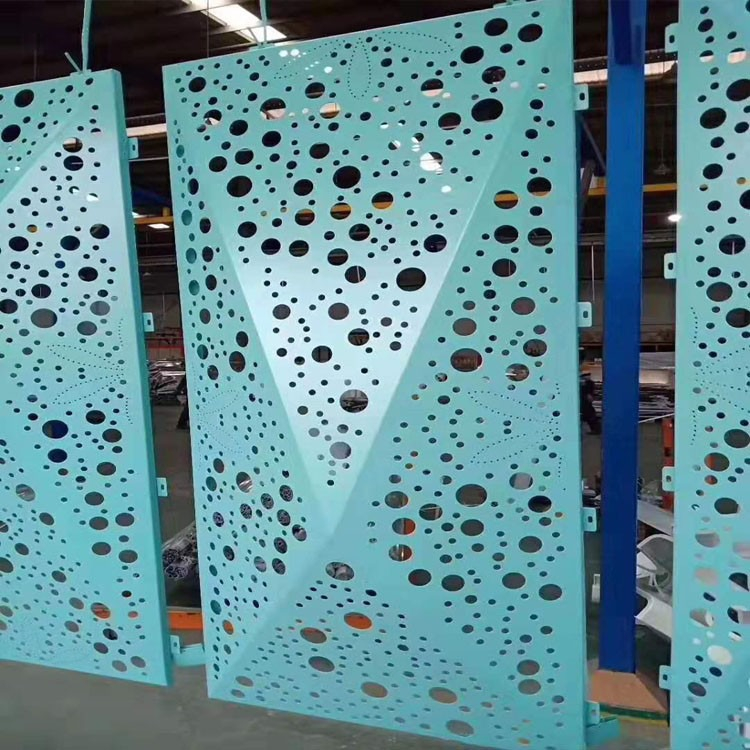

Hyperbolic baking paintAluminum veneerIt is a new type of building material, and its manufacturing process and technology are very unique. The following will provide a detailed introduction to the production process and technology of hyperbolic baking paint aluminum veneer.

1、 Production process

1. Material preparation: The production of hyperbolic baking paint aluminum veneer requires the use of high-quality aluminum alloy materials and fluorocarbon coatings. In the material preparation stage, strict quality testing is required to ensure that the material's performance meets the requirements.

2. Cutting and processing: Cut and process aluminum alloy materials according to design requirements to create the desired shape of aluminum veneer. Cutting processing is one of the most critical steps in the entire manufacturing process, which requires ensuring dimensional accuracy and surface smoothness.

3. Surface treatment: Surface treatment is carried out on the cut aluminum veneer, including grinding, polishing and other processes, to improve the flatness and glossiness of the aluminum veneer surface.

4. Spraying fluorocarbon coating: Place the surface treated aluminum veneer in the spraying room and evenly spray the fluorocarbon coating on the aluminum veneer through a spraying machine, forming beautiful arcs and curves.

5. Baking and curing: Place the sprayed aluminum veneer in a baking room and cure the fluorocarbon coating through high-temperature baking, thereby improving the corrosion resistance and UV resistance of the aluminum veneer.

2、 Technical points

1. Cutting and processing technology: Cutting and processing is one of the key steps in producing hyperbolic baked paint aluminum veneer. High precision cutting equipment and professional operating techniques are required to ensure the dimensional accuracy and surface smoothness of aluminum veneer.

2. Surface treatment technology: Surface treatment is one of the important means to improve the flatness and glossiness of aluminum veneer surface. Efficient surface treatment equipment and professional operating techniques are required to ensure optimal surface treatment results.

3. Spray coating technology: Spray coating is one of the key processes in producing hyperbolic baked paint aluminum veneer. Efficient spraying equipment and professional operating techniques are required to ensure that fluorocarbon coatings are evenly sprayed onto aluminum veneers, forming beautiful arcs and curves.

4. Baking and curing technology: Baking and curing is one of the key steps to improve the corrosion resistance and UV resistance of hyperbolic baked aluminum veneer. High temperature baking equipment and scientific baking processes are required to ensure the optimal curing effect of fluorocarbon coatings.

The production process and technology of hyperbolic baking paint aluminum veneer are very complex, requiring advanced equipment and professional operating techniques to ensure product quality meets requirements. In the future, with the continuous advancement of technology and the increasing demand for personalized customization, it is believed that hyperbolic baking paint aluminum veneer will be more widely used and developed.

Customer service QQ

Customer service QQ