Industry information

Company News

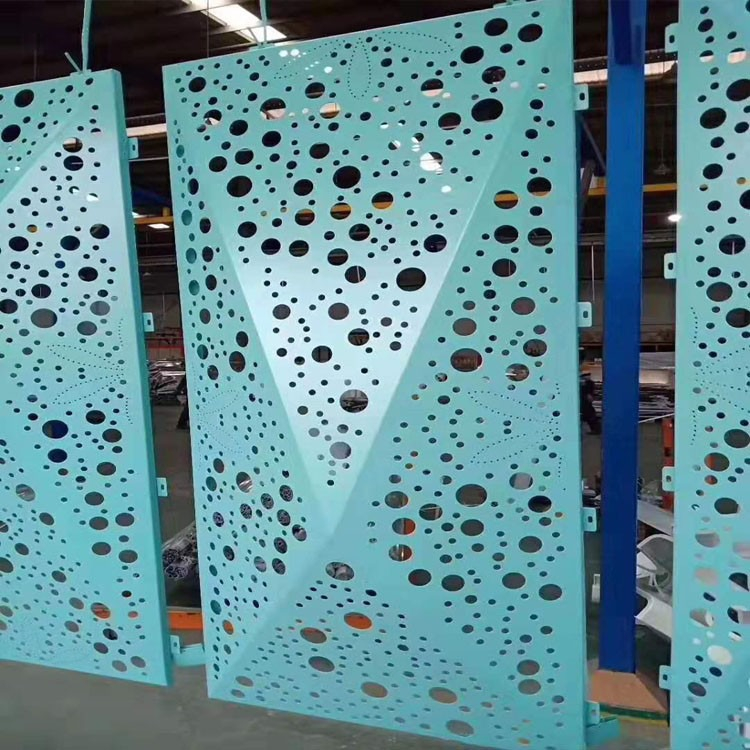

- Punched aluminum veneer, the new darling of fashionable architecture

- How much do you know about curtain wall aluminum veneer: the fashionable outerwear of architecture?

- Fluorocarbon aluminum veneer: a green transformation of new building materials

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- Aluminum veneer, the 'hidden hero' of modern architecture

Industry dynamics

- How do aluminum veneer manufacturers ensure product quality?

- Aluminum plate punching, the perfect combination of fashion and practicality!

- Aluminum veneer curtain wall, the fashionable coat of architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: the new darling of "black technology" in the construction industry

Frequently asked questions

- How does aluminum veneer affect indoor temperature?

- What are the maintenance methods for aluminum veneer?

- Is there a wide range of color options for aluminum veneer?

- Can aluminum veneer be used for building canopy design?

- Is the use of aluminum veneer limited by geographical environment?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Fire performance test report of outdoor wall aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-24 05:38:22

- Click:0

Outdoor wallAluminum veneerThe fire resistance performance is one of its important safety performance. Below, we will introduce in detail the fire resistance test report of outdoor wall aluminum veneer.

1、 Testing method

1. Select a certain number of outdoor wall aluminum veneer samples for combustion testing.

2. Set the corresponding temperature and oxygen concentration in the laboratory, and place the sample in the test furnace for combustion testing.

3. Evaluate the sample based on indicators such as combustion time, smoke density, and flame height.

2、 Test results

1. Sample number Flame height (cm) Burning time (s) Smoke density (g/m3)

001 25 100 120

002 30 80 160

003 28 120 140

004 22 90 180

005 20 110 150

3、 Result analysis

According to the test results, it can be seen that there are differences in the fire resistance performance of the samples. The sample with the code 001 has a combustion time of 100 seconds and a smoke density of 120 grams per cubic meter, which meets the requirements of relevant national standards; The samples numbered 002, 003, 004, and 005 have certain safety hazards and need to be improved and upgraded.

4、 Suggested measures

1. Strengthen the quality control of raw materials to ensure that the fire resistance of outdoor wall aluminum veneer meets national standards.

2. Improve the level of production technology, adopt advanced production equipment and technology, and enhance product quality and safety.

3. Strengthen product testing and supervision, and promptly handle and eliminate outdoor wall aluminum veneers that do not meet standards.

The fire resistance of outdoor wall aluminum veneer is one of its important safety performance, which requires strict testing and supervision. Only by strengthening quality control and supervision can the safety and reliability of outdoor wall aluminum panels be guaranteed.

Customer service QQ

Customer service QQ