Industry information

Company News

- Customized aluminum veneer to make buildings more efficient and energy-saving

- Aluminum veneer curtain wall: the magnificent coat of modern architecture

- Aluminum veneer curtain wall, the fashionable "coat" of architecture

- Aluminum veneer curtain wall: the beauty of architecture, witness to details

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer curtain wall, the secret weapon of architectural aesthetics!

- 🌟 The Beauty of Holes ": Unveiling the Unique Charm of Punched Aluminum Veneers!

- Aluminum veneer easily achieves perfect installation

- Multiple color and texture options for aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How does aluminum veneer affect indoor temperature?

- What is the thermal insulation performance of aluminum veneer?

- Is the use of aluminum veneer limited by geographical environment?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- What are the maintenance methods for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production efficiency of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 20, 2025 00:23:38

- Click:0

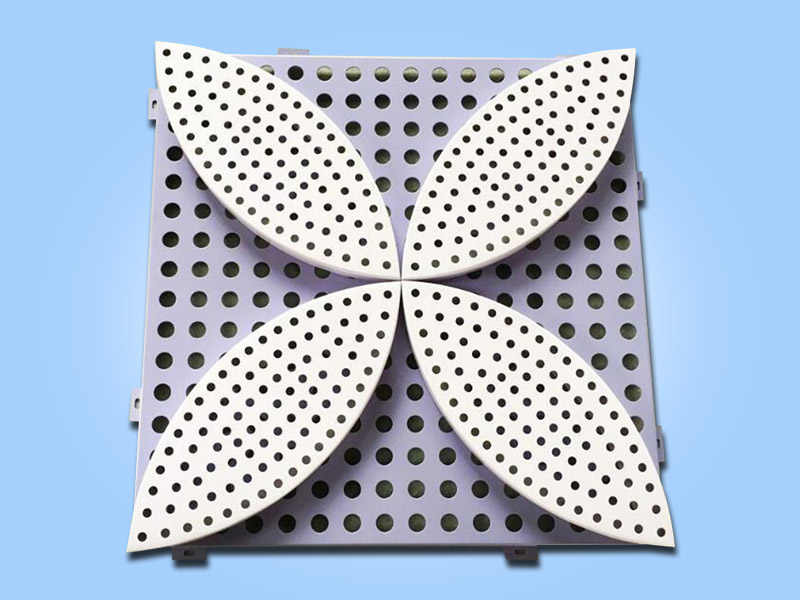

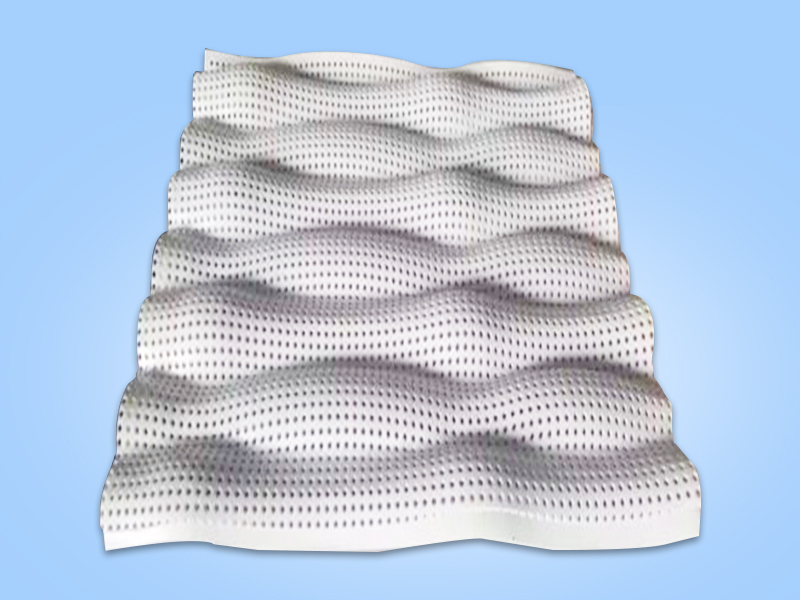

Aluminum veneerAs a common building material, its production efficiency is also an important consideration for customers when choosing to use this product. This article will provide a detailed introduction to the production efficiency of aluminum veneer.

1、 Production process

The production process of aluminum veneer has a significant impact on its production efficiency. In the production process, advanced production techniques and equipment are required to improve production efficiency and product quality. For example, using automated production lines and CNC machine tools can significantly improve production efficiency while also ensuring product accuracy and consistency. Other production processes such as cold rolling, hot rolling, etc. can also be used to further improve the production efficiency of aluminum veneer.

2、 Selection of raw materials

The raw materials of aluminum veneer also have a certain impact on its production efficiency. High quality aluminum alloy sheets have high strength and hardness, which can reduce losses and scrap rates during processing, thereby improving production efficiency. When purchasing aluminum veneer, it is necessary to choose high-quality aluminum alloy sheets produced by reputable manufacturers to ensure their production efficiency.

3、 Personnel management

The production of aluminum veneer requires a large amount of manpower input, so personnel management is also an important factor affecting production efficiency. Enterprises need to establish a sound personnel management system, including recruitment, training, assessment, and other aspects, to improve employees' skill levels and work efficiency. It is also necessary to pay attention to the working environment and welfare benefits of employees to stimulate their work enthusiasm and creativity.

4、 Equipment maintenance

The maintenance of equipment is also one of the important factors affecting the production efficiency of aluminum veneer. During the production process, it is necessary to regularly inspect and maintain the equipment, promptly identify and solve problems, in order to ensure the normal operation and production efficiency of the equipment. We also need to pay attention to equipment updates and technological upgrades to adapt to changes in market demand and improve production efficiency.

5、 Quality Management

Quality management is also one of the important means to ensure the production efficiency of aluminum veneer. Enterprises need to establish a sound quality management system, strictly controlling every link from raw material procurement to production and processing to finished product inspection, to ensure that product quality meets standard requirements. It is also necessary to regularly inspect and maintain the production line, promptly identify and solve problems, in order to improve production efficiency and product quality.

The production efficiency of aluminum veneer is influenced by various factors, including production processes, selection of raw materials, personnel management, equipment maintenance, and quality management. Enterprises need to pay attention to product quality and service level, and actively respond to national environmental policies and requirements, providing customers with healthier and more environmentally friendly building decoration materials. The government also needs to strengthen the supervision and management of the aluminum veneer industry to promote its sustainable development.

Customer service QQ

Customer service QQ