Industry information

Company News

- Unveiling Aluminum Veneers for Curtain Walls: The Fashionable Coat of Architecture

- Hole art, new trend of aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the fashionable new favorite of modern architecture

Industry dynamics

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer customization, creating personalized space and new fashion

- The charm of aluminum veneer curtain wall: the fashionable coat of modern architecture

- Unveiling the magical charm of curtain wall aluminum veneer

- How to choose suitable aluminum veneer materials for outdoor exterior walls

Frequently asked questions

- Can aluminum veneer be used for building canopy design?

- Is the use of aluminum veneer limited by geographical environment?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- What is the thermal insulation performance of aluminum veneer?

- How does aluminum veneer affect indoor temperature?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Unveiling the production process of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-20 05:47:14

- Click:0

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, and corrosion resistance, and has been widely used in the construction industry. The production process of aluminum veneer is one of the important factors affecting its performance and quality. Below, we will reveal the production process of aluminum veneer.

1、 Cold rolling forming production process

Cold rolling forming is a commonly used production process for aluminum veneer, and it is also one of the most common production processes in the current market. This process mainly involves cold rolling aluminum coils to form the desired shape of aluminum veneer. Specifically, the process includes the following steps:

1. Raw material preparation: Cut the aluminum coil into the required size according to a certain specification;

2. Heat treatment: Heat the aluminum coil to a certain softening temperature;

3. Cold rolling processing: Processing aluminum coils through a cold rolling mill to form the desired shape of aluminum veneer;

4. Surface treatment: Surface treatment of processed aluminum veneer, such as anodizing treatment, fluorocarbon spraying treatment, etc.

2、 Hot pressing production process

Hot pressing is an advanced production process for aluminum veneer, which can further improve the strength and hardness of aluminum veneer. This process mainly involves heating, pressing, and cooling aluminum coils to form the desired shape of aluminum veneer. Specifically, the process includes the following steps:

1. Raw material preparation: Cut the aluminum coil into the required size according to a certain specification;

2. Heating: Heat the aluminum coil to a certain softening temperature;

3. Pressure: Place the heated aluminum coil into a pressure machine for pressure processing;

4. Cooling: Cool the pressurized aluminum veneer to make it harder;

5. Surface treatment: Surface treatment of processed aluminum veneer, such as anodizing treatment, fluorocarbon spraying treatment, etc.

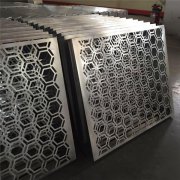

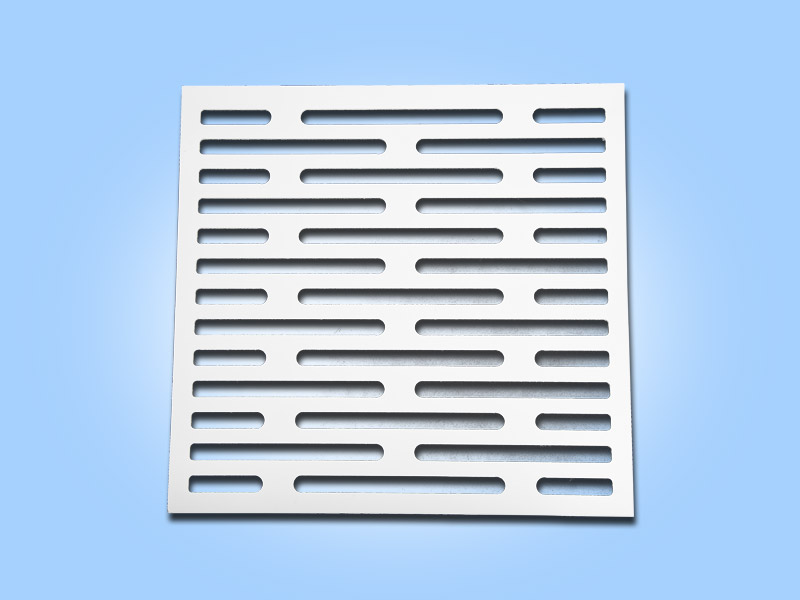

3、 Production process of CNC punching machine forming

Numerical control punch forming is an advanced production process for aluminum veneer, which can achieve high-precision processing of aluminum veneer. This process mainly uses CNC punching machines to punch and bend aluminum coils, forming the desired shape of aluminum veneer. Specifically, the process includes the following steps:

1. Raw material preparation: Cut the aluminum coil into the required size according to a certain specification;

2. CNC punching machine processing: punching, bending and other processing of aluminum coils through CNC punching machines;

3. Surface treatment: Surface treatment of processed aluminum veneer, such as anodizing treatment, fluorocarbon spraying treatment, etc.

The production process of aluminum veneer mainly includes various methods such as cold rolling forming, hot pressing forming, and CNC punching forming. Different production processes will have varying impacts on the performance and quality of aluminum veneer. Consumers need to choose aluminum veneer according to their actual needs and pay attention to choosing products produced by reputable manufacturers to ensure product quality and performance.

Customer service QQ

Customer service QQ