Industry information

Company News

- Aluminum veneer: the latest fashion trend in the construction industry, reveal its charm!

- Aluminum veneer curtain wall: Unveiling the "coat" of modern architecture

- Aluminum veneer: the fashionable outerwear of modern architecture

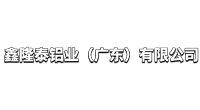

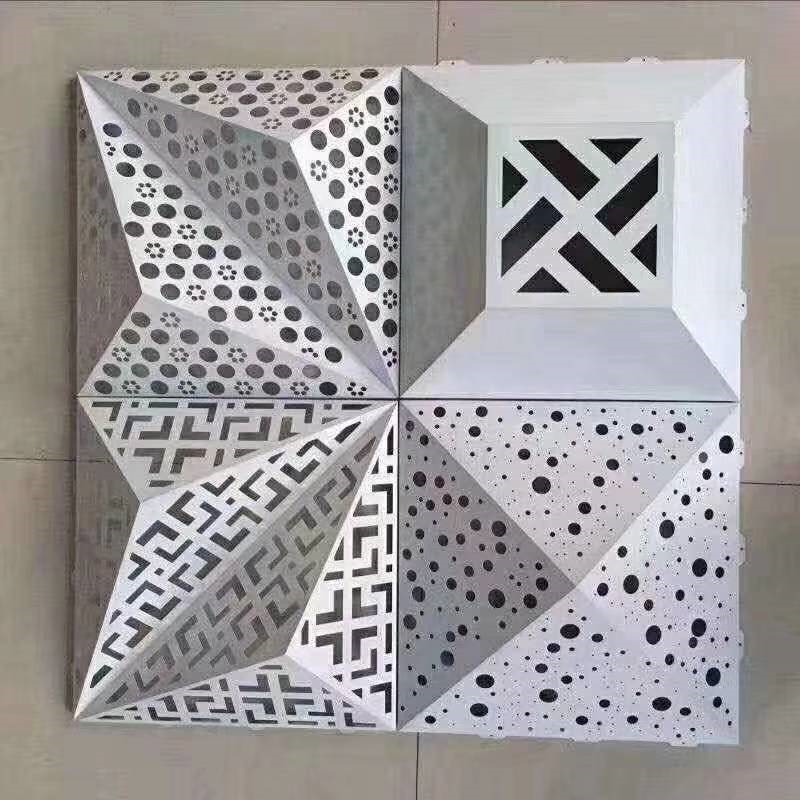

- Punched aluminum veneer: the new darling of modern architecture!

- Punched aluminum veneer: the fashionable new favorite of modern architecture

Industry dynamics

- Curtain wall aluminum veneer: a fashionable outerwear for modern architecture

- Curtain wall aluminum veneer: the new darling of architectural art

- Analysis of the Development Trend of Wood Grain 2.0mm Aluminum Veneer Market

- Fluorocarbon aluminum veneer: the "invisible warrior" of modern architecture

- Aluminum veneer customization, creating exclusive space aesthetics

Frequently asked questions

- Is the use of aluminum veneer limited by geographical environment?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- How sustainable is aluminum veneer?

- What is the thermal insulation performance of aluminum veneer?

- What are the maintenance methods for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the corrosion resistance cycle of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-14 14:10:47

- Click:0

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its corrosion resistance is one of the important factors affecting its service life and aesthetic appearance. The following will provide a detailed introduction to the corrosion resistance cycle of aluminum veneer and its influencing factors.

1. Definition of anti-corrosion cycle

The corrosion resistance cycle of aluminum veneer refers to its ability to resist factors such as oxidation and corrosion in natural environments. Generally speaking, the longer the corrosion resistance cycle of aluminum veneer, the higher its service life and aesthetics.

1. Factors affecting the corrosion resistance cycle

The corrosion resistance of aluminum veneer is influenced by various factors, including:

(1) The material and structure of aluminum veneer;

(2) Surface treatment process;

(3) Environmental temperature and humidity;

(4) Usage status and maintenance status, etc.

1. Testing method for corrosion resistance cycle

In order to test the corrosion resistance of aluminum veneer, the following methods are generally used:

(1) Visual inspection method: Evaluate the corrosion resistance of aluminum veneer by visually observing whether there is obvious oxidation, corrosion, and other conditions on the surface;

(2) Quality inspection method: Evaluate the corrosion resistance of aluminum veneer by conducting quality inspections on indicators such as color uniformity and hardness;

(3) Artificial painting method: By manually painting or spraying, the surface texture and color of aluminum veneer are improved, thereby enhancing its corrosion resistance.

1. Application scenarios of anti-corrosion cycle

The corrosion resistance cycle of aluminum veneer is mainly applied in fields such as construction and decoration. For example, in commercial office buildings, hotels, hospitals and other places, aluminum veneer with good durability and aesthetics needs to be selected; In outdoor environments, it is necessary to choose aluminum veneer with good corrosion resistance and wear resistance.

How to extend the corrosion resistance period of aluminum veneer?

In order to extend the corrosion resistance cycle of aluminum veneer, enterprises can take the following measures:

(1) Optimize the design and selection of aluminum veneer, choose materials with good strength and stability;

(2) Strengthen the research and improvement of surface treatment processes, such as anodizing, electrophoretic coating, etc;

(3) Strengthen daily maintenance and upkeep work, regularly clean the surface of aluminum veneer to maintain its good appearance and performance. New materials and technologies such as self-cleaning coatings and antibacterial materials can also be used to improve the corrosion resistance of aluminum veneer.

The corrosion resistance cycle of aluminum veneer is one of the important factors affecting its service life and aesthetics. Enterprises should choose suitable aluminum veneers according to actual needs and strictly follow quality standards for production and processing to ensure product quality and safety performance. We should also strengthen the management and maintenance of aluminum veneer to improve its corrosion resistance and extend its service life.

Customer service QQ

Customer service QQ