Industry information

Company News

- Fluorocarbon aluminum veneer: the 'hidden hero' of modern architecture

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the fashionable outerwear of modern architecture

- Fluorocarbon aluminum veneer, the new trend of architectural beauty

Industry dynamics

- Competitive Analysis of Aluminum Veneer Customization Market

- Customized exclusive appearance carved roller coated aluminum veneer to assist personalized architectural design

- Curtain wall aluminum veneer, creating the beauty of modern architecture

- Fluorocarbon aluminum veneer: the "black technology" in the construction industry

- Aluminum veneer: a new favorite in the construction industry, perfectly integrating environmental protection and aesthetics!

Frequently asked questions

- How does aluminum veneer affect indoor temperature?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- Can aluminum veneer be applied to the exterior design of sports buildings?

- What is the thermal expansion coefficient of aluminum veneer?

- Is there a wide range of color options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to Processing Technology and Equipment for Aluminum Veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-13 22:54:47

- Click:0

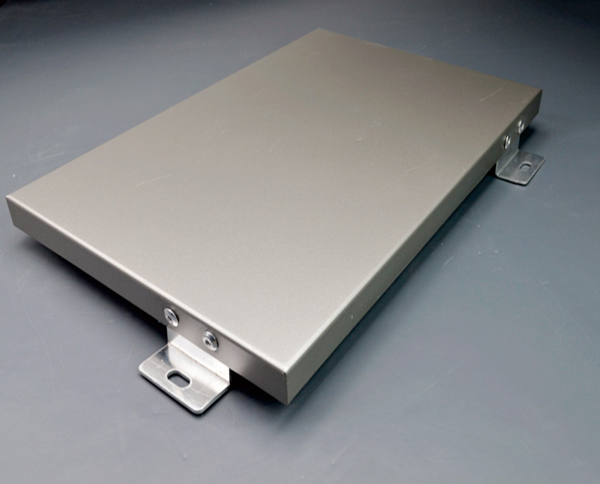

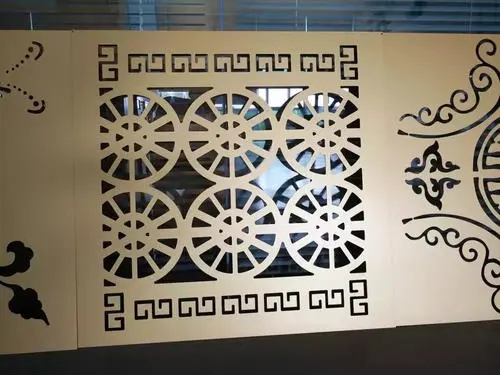

Aluminum veneerAs a new type of building material, it has been widely used in modern architecture. The processing technology and equipment of aluminum veneer are important factors affecting its quality and performance. This article will provide a detailed introduction to the processing technology and equipment of aluminum veneer from the following aspects.

1、 Processing technology of aluminum veneer

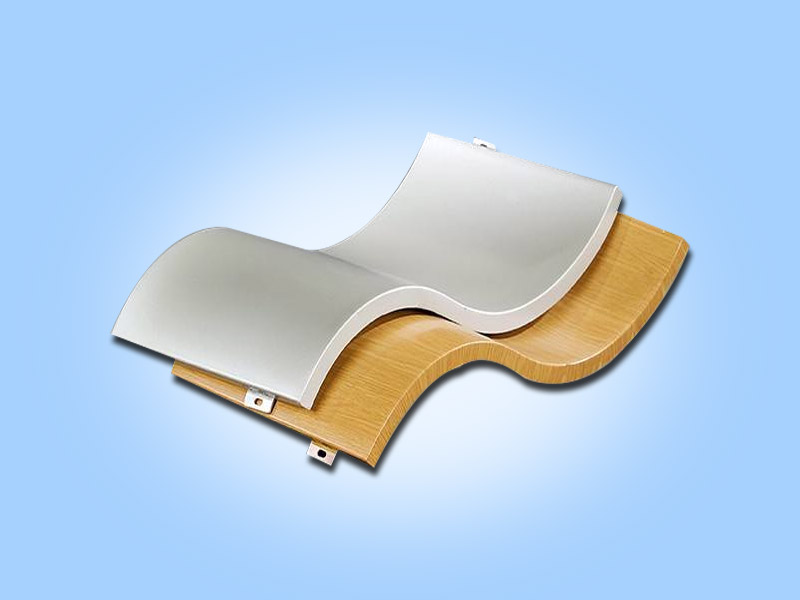

The processing technology of aluminum veneer mainly includes several methods such as stamping, bending, and welding. Stamping is the most commonly used process in the production of aluminum veneer, which can use molds to stamp aluminum sheets into various shapes and sizes of aluminum veneer products. Bending forming is the process of bending the stamped aluminum plate to meet different architectural design requirements. Welding forming is the process of combining multiple aluminum plates together through welding to form larger aluminum veneer products.

2、 Processing equipment for aluminum veneer

The processing equipment for aluminum veneer mainly includes several types of equipment such as punching machines, bending machines, welding machines, etc. Punching machine is the most commonly used equipment in the production of aluminum veneer. It can punch aluminum sheets through molds to form various shapes and sizes of aluminum veneer products. The bending machine is used to bend the stamped aluminum plate to meet different architectural design requirements. The welding machine combines multiple aluminum plates together by welding to form larger aluminum veneer products. There are also some auxiliary equipment, such as cutting machines, sanding machines, etc., used for subsequent processing of aluminum veneers.

3、 The development trend of processing technology and equipment

With the development of technology and people's increasing demand for environmental protection and energy conservation, the processing technology and equipment for aluminum veneer are also constantly evolving and improving. For example, in recent years, some intelligent processing equipment has emerged, such as CNC punching machines, laser cutting machines, etc., which can achieve automated production and precise control. Some new materials and technologies have also been applied in the production of aluminum veneer, such as 3D printing technology, surface spraying technology, etc., which can improve the quality and performance of aluminum veneer.

The processing technology and equipment of aluminum veneer are important factors affecting its quality and performance. Only by selecting appropriate processing techniques and equipment, and continuously improving and perfecting them, can high-quality and high-performance aluminum veneer products be produced.

Customer service QQ

Customer service QQ