Industry information

Company News

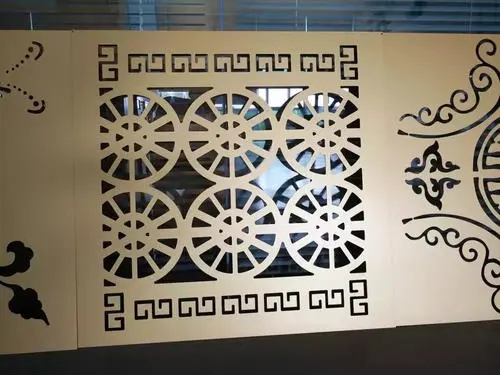

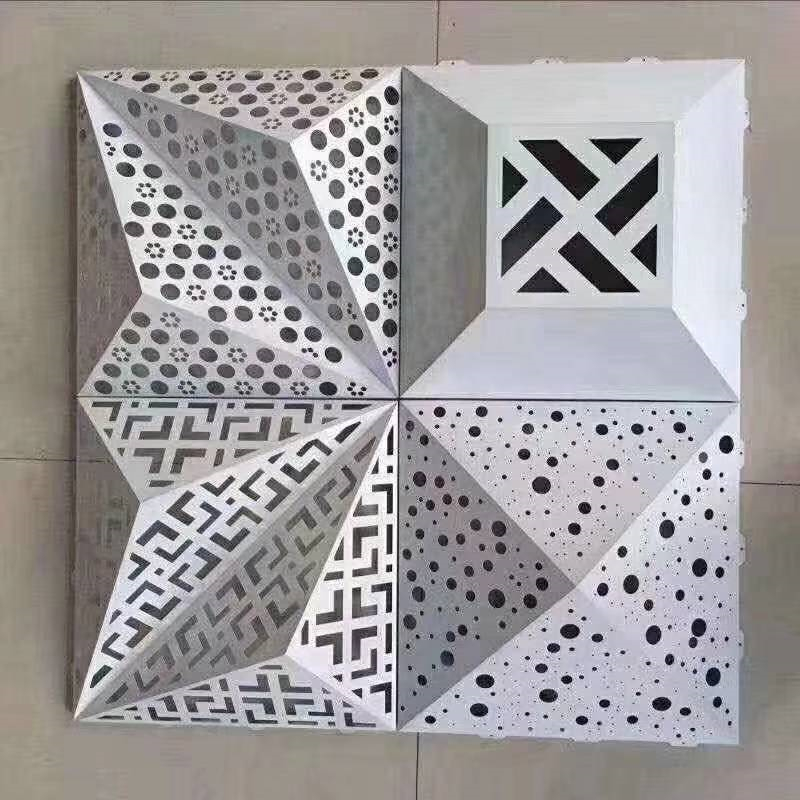

- Aluminum veneer customization, creating a new trend of personalized space

- Modern interpretation of aluminum veneer: perfect fusion of light luxury and practicality

- Aluminum veneer customization, creating a new proposition for personalized space!

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- Exploring Fluorocarbon Aluminum Veneer: An Environmentally Friendly Choice, the Secret Weapon of Future Architecture

Industry dynamics

- Aluminum veneer: providing excellent wind resistance performance for building exterior walls

- Understand the performance characteristics of aluminum veneer curtain walls

- Aluminum veneer: the green guardian of modern architecture

- Competitive Analysis of Aluminum Veneer Customization Market

- Aluminum veneer customization, creating exclusive space aesthetics

Frequently asked questions

- Can aluminum veneer be used for building canopy design?

- What is the thermal expansion coefficient of aluminum veneer?

- Can aluminum veneer be applied to the exterior design of sports buildings?

- How sustainable is aluminum veneer?

- Can the insulation function of aluminum veneer be long-lasting and effective?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production cost analysis of aluminum veneer manufacturers

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 4, 2025 21:16:33

- Click:0

Aluminum veneerAs a building decoration material, its production cost is one of the important factors for customers to choose. Below is a detailed introduction to the production cost analysis of aluminum veneer manufacturers.

1、 Raw material cost

1. Aluminum price: The main raw material for aluminum veneer is aluminum, and its price is affected by factors such as market supply and demand, international aluminum price fluctuations, etc.

2. Surface treatment material cost: There are various surface treatment methods for aluminum veneer, such as spraying, anodizing, powder coating, etc. The material cost is also affected by market supply and demand, raw material prices, and other factors.

3. Other auxiliary material costs: The production of aluminum veneer also requires the use of some auxiliary materials, such as glue, screws, etc., and the cost of these materials will also have an impact on the total cost.

2、 Labor cost

1. Production worker wages: The production of aluminum veneer requires a large amount of manual operation, including aluminum processing, surface treatment, assembly, and other links. Labor wages are also an important component of production costs.

2. Salary of management personnel: The production of aluminum veneer requires certain management coordination, including production planning, quality control, personnel training, and other aspects. The salary of management personnel will also have an impact on the total cost.

3、 Equipment depreciation and maintenance costs

1. Depreciation of production equipment: The production of aluminum veneer requires the use of some mechanical equipment, such as cutting machines, spraying machines, etc., and the depreciation cost of these equipment is also part of the production cost.

2. Equipment maintenance costs: The maintenance of aluminum veneer production equipment also requires certain expenses, including repair and maintenance, parts replacement, etc., which will also have an impact on the total cost.

4、 Energy and transportation costs

1. Energy consumption: The production of aluminum veneer requires a certain amount of energy, such as electricity, gas, etc., and the consumption of energy also incurs certain costs.

2. Transportation costs: After the production of aluminum veneer is completed, transportation and distribution are required, which also incurs certain expenses.

The production costs of aluminum veneer manufacturers mainly include raw material costs, labor costs, equipment depreciation and maintenance costs, as well as energy and transportation costs. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ