Industry information

Company News

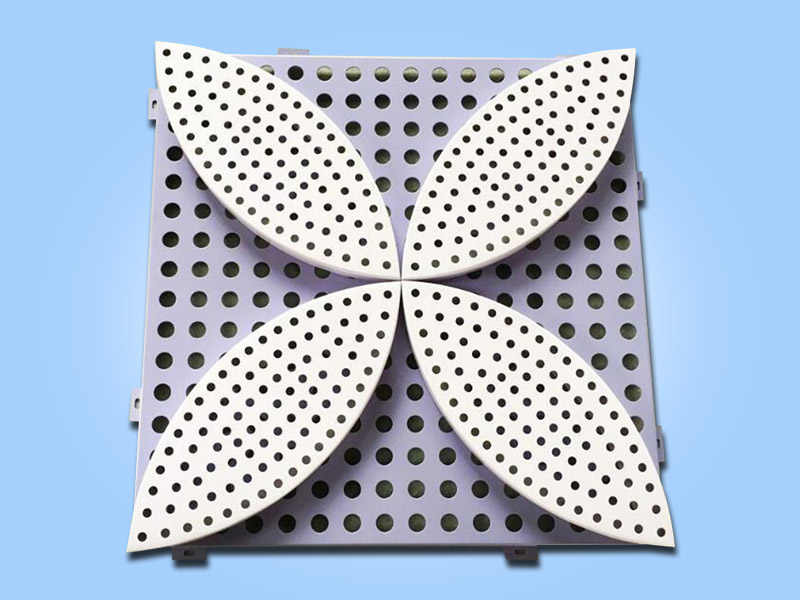

- Punched aluminum veneer: a fashionable choice in modern architecture

- Curtain wall aluminum veneer: creating a new style of modern architecture

- Exploring the unique charm of fluorocarbon aluminum veneer

- Aluminum veneer: the latest fashion trend in the construction industry, revealing its charm!

- Fluorocarbon aluminum veneer: a perfect combination of architectural aesthetics and durability

Industry dynamics

- Fluorocarbon aluminum veneer, the "mysterious coat" of fashionable architecture

- Fluorocarbon aluminum veneer: the 'invisible hero' of the construction industry

- High quality punched aluminum veneer manufacturer

- Aluminum veneer curtain wall: the new aesthetic favorite of modern architecture

- Aluminum veneer prices - Corporate social responsibility and business model innovation

Frequently asked questions

- Is there a wide range of color options for aluminum veneer?

- What are the maintenance methods for aluminum veneer?

- What is the thermal insulation performance of aluminum veneer?

- What is the thermal expansion coefficient of aluminum veneer?

- How does aluminum veneer affect indoor temperature?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of the production process and characteristics of brushed aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 14:35:38

- Click:0

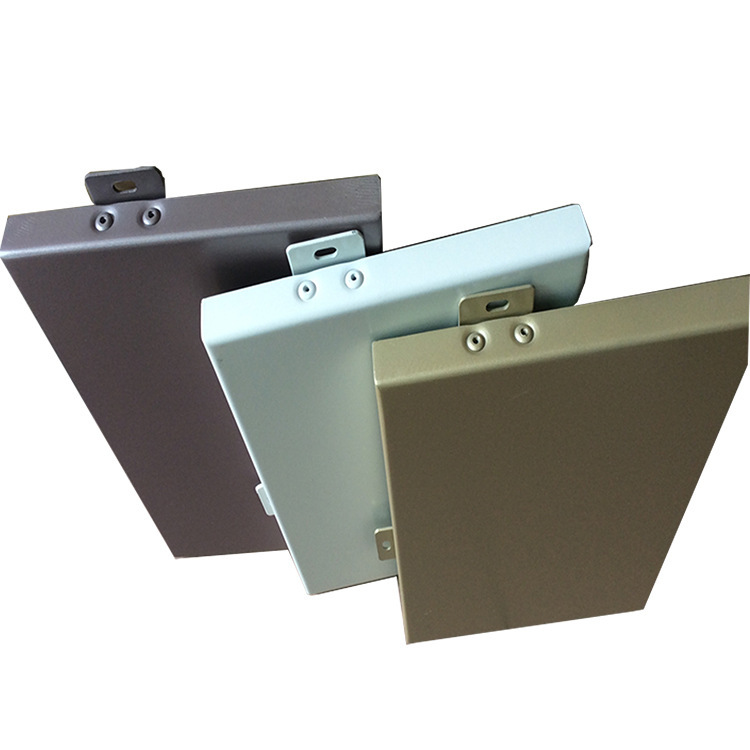

wire drawingAluminum veneerIt is a high-end building material with excellent performance and beautiful appearance. Its production process mainly includes the following steps:

1. Selection of raw materials: The main raw material for brushed aluminum veneer is aluminum alloy sheet, with 1 series, 3 series, and 5 series alloys as the main raw materials. These materials have high strength and corrosion resistance, and are an important foundation for producing high-quality brushed aluminum veneer.

2. Cutting and processing: Cut and process the raw materials according to the design requirements to obtain the required aluminum plate size and shape. This step requires the use of high-precision cutting equipment to ensure the accuracy and surface smoothness of the aluminum plate.

3. Rolling processing: Place the cut aluminum plate into a rolling mill for rolling processing to achieve the desired thickness and width. This step requires attention to controlling the thickness and width of the aluminum plate to ensure the quality of subsequent processing.

4. Wire drawing processing: Place the rolled aluminum plate into a wire drawing machine for wire drawing processing, so that its surface presents a texture effect similar to silk. This step requires controlling the tension and speed of the wire drawing machine to ensure the uniformity and consistency of the wire drawing effect.

5. Surface treatment: Surface treatment of aluminum plates after wire drawing processing, including anodizing, spraying, electrophoresis and other processes, to improve their corrosion resistance and decorative properties. This step requires selecting a suitable surface treatment process and strictly controlling the quality of the treatment process.

The characteristics of brushed aluminum veneer are mainly manifested in the following aspects:

1. High strength and corrosion resistance: The brushed aluminum veneer is made of high-strength aluminum alloy material, which has high strength and corrosion resistance, and can maintain stable performance in various harsh environments.

2. Beautiful appearance: The surface of brushed aluminum veneer presents a texture effect similar to silk, with high decorative and aesthetic value, which can add a unique artistic atmosphere to the building.

3. Easy to process and install: Drawing aluminum veneer can be processed in various ways, such as cutting, rolling, drawing, etc., and can also be easily installed and maintained.

As a high-end building material, brushed aluminum veneer has excellent performance and beautiful appearance, and is widely used in fields such as construction, decoration, and transportation. With the continuous advancement of technology and the increasing demand for building material quality, it is believed that brushed aluminum veneer will be widely used and developed in the future.

Customer service QQ

Customer service QQ