Industry information

Company News

- Punched aluminum veneer, the "fashionable outerwear" of modern architecture

- Aluminum veneer: a modern interpretation of light luxury materials

- Aluminum veneer: a light luxury choice for industrial aesthetics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Analysis of the Price and Cost Structure of Aluminum Veneer

- What is the discoloration performance of aluminum veneer?

- Aluminum veneer: the "hidden master" in light luxury building materials

- Analysis of Types and Characteristics of Aluminum Veneers

- Great Wall exterior aluminum veneer creates a new benchmark for building exterior walls

Frequently asked questions

- How does aluminum veneer affect indoor temperature?

- Is there a wide range of color options for aluminum veneer?

- Can aluminum veneer be applied to the exterior design of sports buildings?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- What are the maintenance methods for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and application skills of curved painted aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-01 18:05:20

- Click:0

Arc shaped baking paintAluminum veneerIt is a high-end building material, and its production process and application techniques have attracted much attention. Below, we will provide a detailed introduction to the production process and application techniques of curved painted aluminum veneer.

1、 Production process

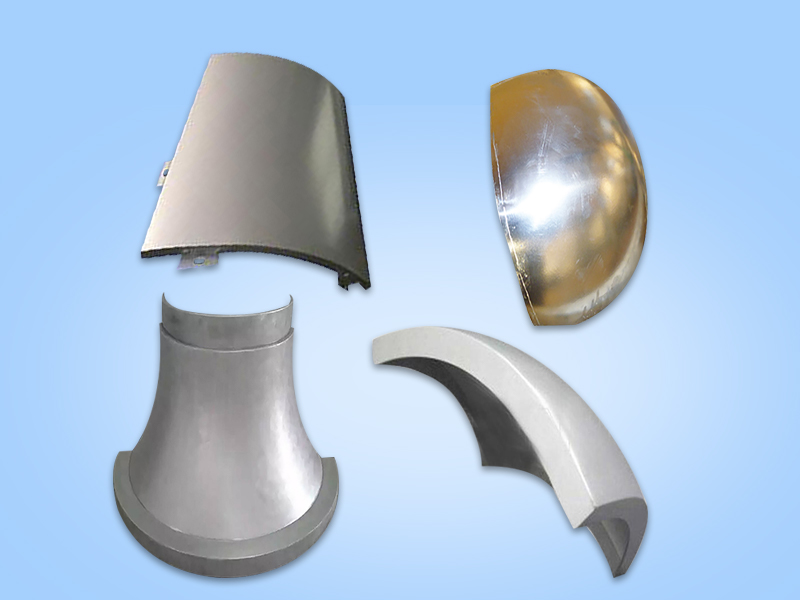

1. Raw material preparation: The main material for curved painted aluminum veneer is aluminum alloy sheet, which requires strict inspection and screening to ensure compliance with requirements.

2. Cutting and processing: Cut and process the aluminum alloy sheet according to the design requirements to form the required aluminum plate.

3. Rolling forming: The aluminum plate is rolled by a rolling machine to form an arc-shaped shape.

4. Surface treatment: Surface treatment is carried out on the formed curved aluminum plate, including anodizing, fluorocarbon spraying, etc., to improve its corrosion resistance and aesthetics.

5. Coating treatment: After mixing the coating material and solvent, the coating is evenly applied to the surface of the aluminum alloy sheet through a roller coating machine.

6. Baking and curing: After the coating is completed, it needs to be cured by baking or other methods to firmly adhere the coating to the surface of the aluminum alloy sheet.

2、 Application skills

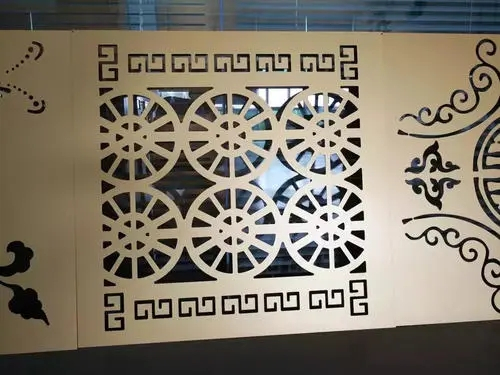

1. Color matching: Arc painted aluminum veneer can be coated with various colors, including white, black, silver, etc. The appropriate color matching should be selected according to different indoor environments and decorative styles.

2. Space layout: Curved painted aluminum veneer can increase the sense of indoor space and luxury. The appropriate size and quantity of curved surfaces should be selected according to different indoor space sizes and layouts.

3. Surface treatment methods: Arc painted aluminum veneer can undergo various surface treatment methods, such as anodizing, fluorocarbon spraying, etc. The appropriate surface treatment method should be selected according to different usage environments and requirements.

4. Intelligent application: With the development of technology, curved painted aluminum veneer will gradually realize intelligent application, such as monitoring indoor temperature and humidity parameters through sensors, automatically adjusting indoor temperature and humidity, improving comfort and energy-saving effect. This can not only improve indoor comfort, but also bring more creativity and possibilities to interior design.

3、 Conclusion

The production process and application techniques of curved painted aluminum veneer have a crucial impact on its performance and appearance. In future design, we need to pay more attention to environmental and aesthetic issues, choose more environmentally friendly and beautiful building materials, and create a better living environment for humanity.

Customer service QQ

Customer service QQ