Industry information

Company News

- Aluminum veneer curtain wall: the "gorgeous coat" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Art in Holes - Exploration of Punched Aluminum Veneers

- Aluminum veneer: the fashionable "coat" in modern architecture

- The secret of aluminum veneer: not just its shiny appearance

Industry dynamics

- Punched aluminum veneer, the new aesthetic favorite of modern architecture

- Curtain Wall Aluminum Veneer: A Fashionable Choice in Modern Architecture

- Fire resistance performance and related standards of aluminum veneer

- Punched aluminum veneer, the new trend of aluminum materials!

- Aluminum veneer curtain wall: the beauty of architecture depends on one panel

Frequently asked questions

- What are the maintenance methods for aluminum veneer?

- What is the thermal insulation performance of aluminum veneer?

- Is there a wide range of color options for aluminum veneer?

- What is the thermal expansion coefficient of aluminum veneer?

- How does aluminum veneer affect indoor temperature?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

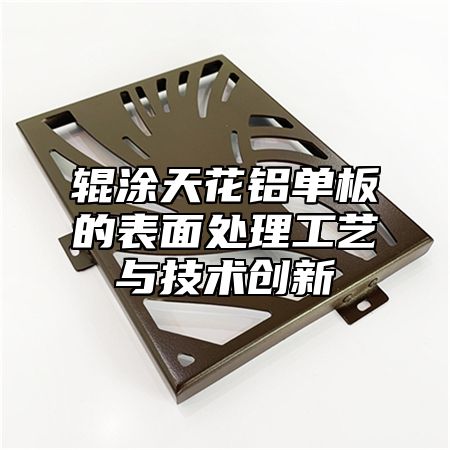

Surface treatment process and technological innovation of roller coated ceiling aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 1, 2025 21:00:28

- Click:0

Roller coated ceilingAluminum veneerIt is a very excellent building material, and its surface treatment process and technological innovation are also very important. Next, we will provide a detailed introduction to the surface treatment process and technological innovation of roller coated ceiling aluminum veneer.

1、 Surface treatment process

The surface treatment process of roller coated ceiling aluminum veneer mainly includes the following steps:

1. Mechanical polishing: Use mechanical equipment to polish the surface of aluminum veneer to remove impurities such as oxide layer and oil stains, in preparation for subsequent coating treatment.

2. Chemical pretreatment: Use chemical agents to pretreat the surface of aluminum veneer, including steps such as degreasing and acid washing, to remove surface oil and oxides, improve coating adhesion and durability.

3. Roll coating primer: Spray the primer evenly on the aluminum veneer to increase the adhesion and durability of the coating.

4. Roll coating topcoat: Spray the topcoat evenly onto the aluminum veneer to achieve the desired color and glossiness.

2、 Technological innovation

In order to improve the surface treatment quality and efficiency of roller coated ceiling aluminum veneer, some new technologies and innovations have emerged in recent years.

1. Electrostatic spraying technology: By using electrostatic spraying technology, the coating can be evenly sprayed onto the aluminum veneer, thereby improving the uniformity and quality of the coating.

2. Non pressure spraying technology: Adopting non pressure spraying technology can reduce coating waste and environmental pollution, while also improving the utilization and efficiency of coatings.

3. Intelligent control system: Adopting an intelligent control system can achieve automated production, thereby improving production efficiency and quality.

4. Environmentally friendly coatings: Using environmentally friendly coatings can reduce pollution to the environment, while also improving the quality and durability of the coating.

The surface treatment process and technological innovation of roller coated ceiling aluminum veneer play a very important role in improving product quality and efficiency. In the future, with the development of technology and continuous improvement of production processes, it is believed that roller coated ceiling aluminum veneer will have broader application prospects.

Customer service QQ

Customer service QQ