Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: a new favorite in construction and a pioneer in environmental protection

- Curtain wall aluminum veneer: the new darling of modern architectural aesthetics

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer curtain wall, the fashionable "coat" of architecture

Industry dynamics

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

- Analyze the advantages and unique features of fluorocarbon aluminum veneer with column wrapping

- Aluminum veneer, creating a new style of modern architecture!

- Aluminum veneer curtain wall: the "invisible cloak" of modern architecture

- How to choose the aluminum veneer specifications and models that meet your needs?

Frequently asked questions

- What is the thermal expansion coefficient of aluminum veneer?

- How sustainable is aluminum veneer?

- Can aluminum veneer be used for building canopy design?

- How does aluminum veneer affect indoor temperature?

- Is there a wide range of color options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

High quality materials and exquisite craftsmanship of engineering ceiling aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 2, 2025 09:47:05

- Click:0

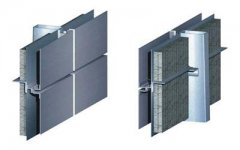

Engineering ceilingAluminum veneerIt is a decorative building material widely used in architecture, commerce, and public places. Its high-quality materials and exquisite craftsmanship make it an indispensable part of modern architecture. This article will provide a detailed introduction to the high-quality materials and exquisite craftsmanship of engineering ceiling aluminum veneer.

1、 High quality materials

1. Aluminum alloy material

The main material of engineering ceiling aluminum veneer is aluminum alloy, which has the advantages of lightweight, high strength, corrosion resistance, and also has good thermal conductivity and sound insulation performance. Compared to other materials, aluminum alloy material is more environmentally friendly and has a longer service life.

1. Surface treatment technology

In order to improve the aesthetics and anti-corrosion performance of engineering ceiling aluminum veneer, surface treatment is usually carried out. The common surface treatment technologies on the market currently include anodizing, spraying, and rolling. Anodizing is the most commonly used surface treatment technique, which can form a hard, wear-resistant, and corrosion-resistant oxide film, giving aluminum veneer better durability and pollution resistance.

2、 Exquisite craftsmanship

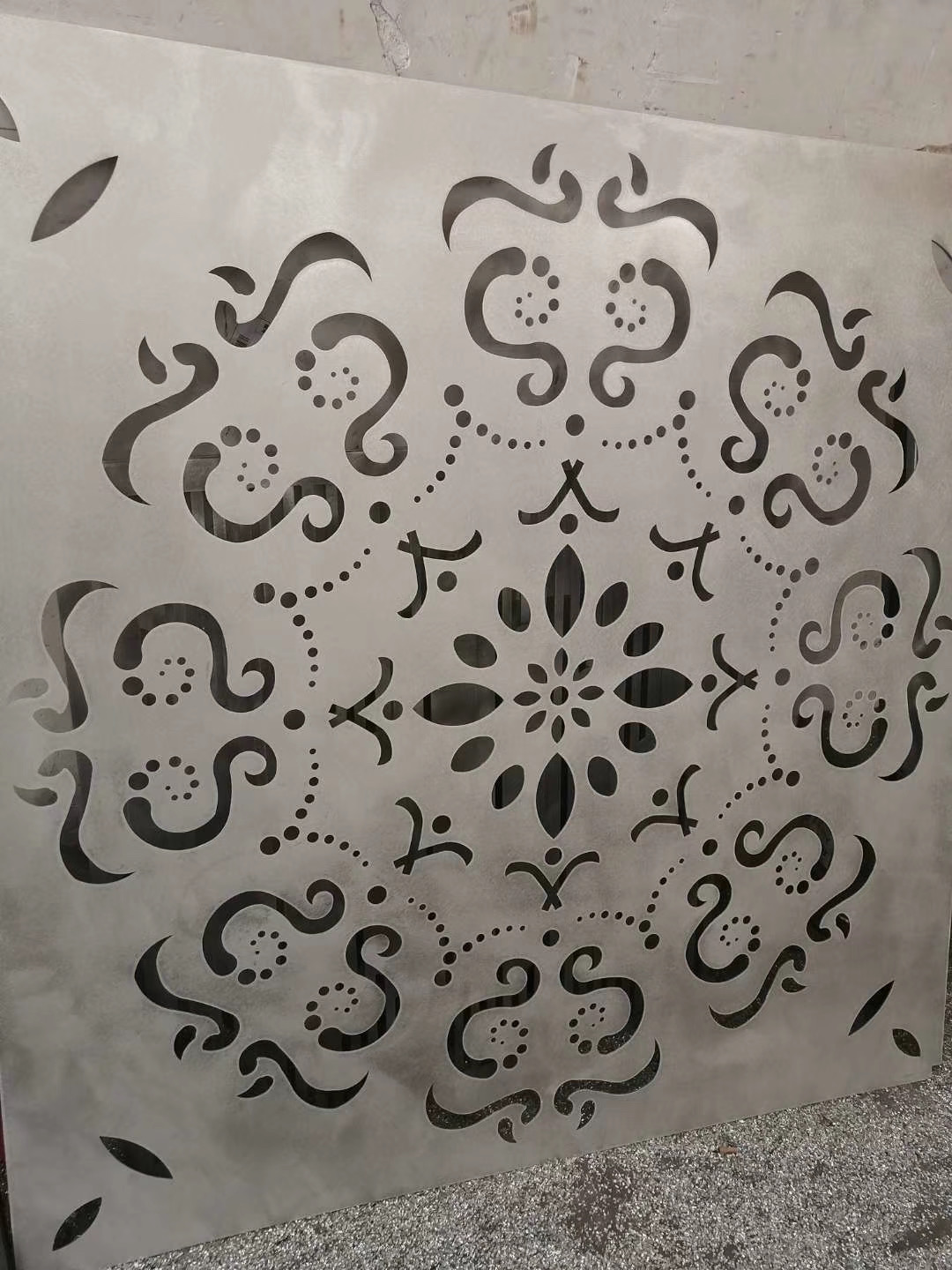

1. Cutting process

In the production process, the aluminum material needs to be cut and processed first. Generally speaking, using a CNC cutting machine for cutting can ensure dimensional accuracy and surface smoothness. During the cutting process, attention should be paid to avoiding scratches and burrs to ensure product quality.

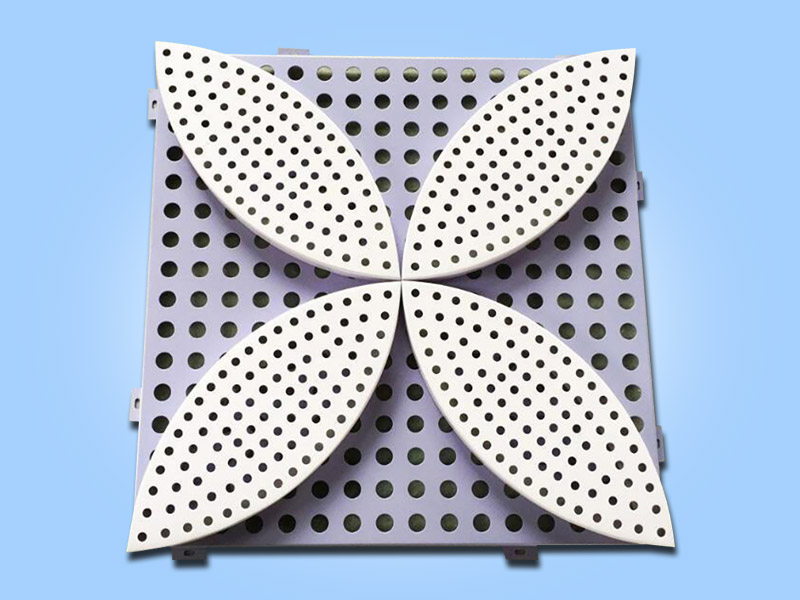

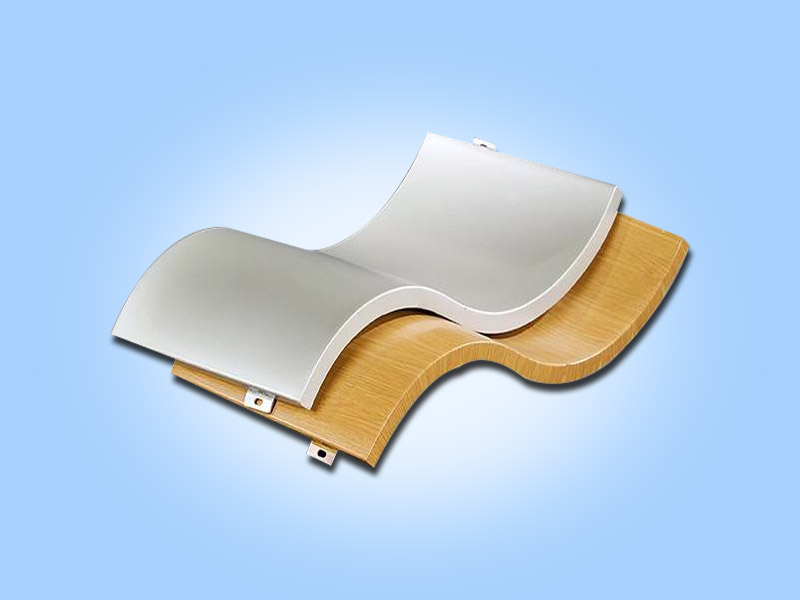

1. Bending process

Bending is one of the important processes in the production of engineering ceiling aluminum veneer. During the bending process, professional equipment and technology are required to ensure that the bending angle and shape of the aluminum veneer meet the design requirements. During the bending process, attention should also be paid to avoiding problems such as cracks and deformation.

1. Welding process

When making engineering ceiling aluminum veneer, welding treatment is usually required. At present, TIG welding technology is mainly used in the market, which can achieve high-quality welding results while avoiding problems such as porosity and weld cracks.

As a high-quality decorative material, the high-quality materials and exquisite craftsmanship of engineering ceiling aluminum veneer are the key factors for its success. In the future development, with the continuous progress and innovation of technology, it is believed that engineering ceiling aluminum veneer will play a more important role in the field of construction.

Customer service QQ

Customer service QQ