Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

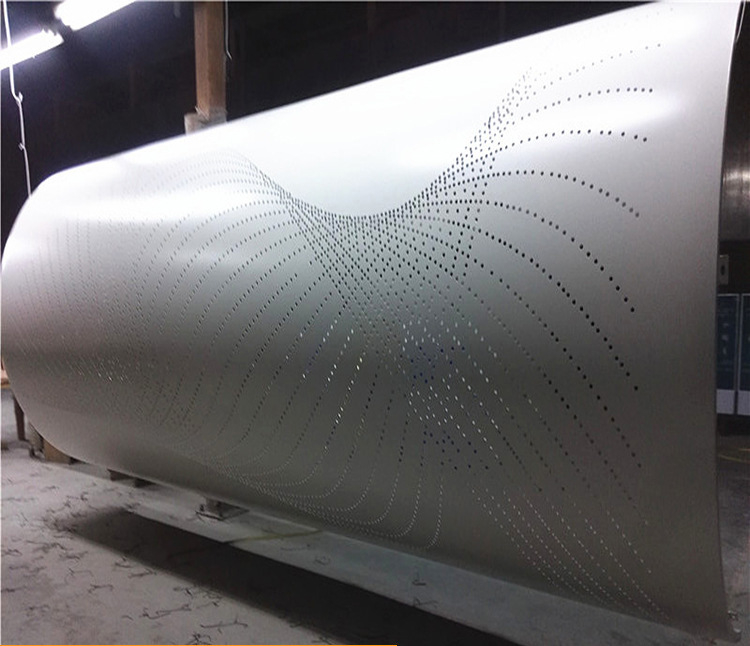

- Unlimited creativity, perforated aluminum veneer creates personalized space

- Curtain wall aluminum veneer, the new darling of architectural aesthetics!

- Aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- Hole Art: Exploration of the Unique Charm of Punched Aluminum Veneer

- Aluminum veneer manufacturers lead industry development with technological innovation

- Aluminum veneer: the fashionable choice for modern architecture

- Application of customized aluminum veneer materials

- Hole Art of Aluminum Veneer: Analysis of the Charm of Punched Aluminum Veneer

Frequently asked questions

- Is there a wide range of color options for aluminum veneer?

- How sustainable is aluminum veneer?

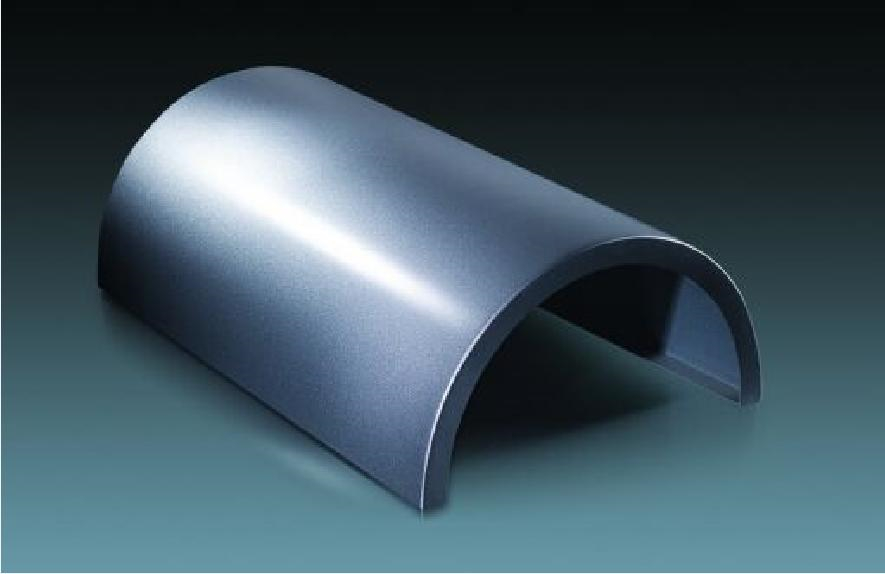

- Can aluminum veneer be used for building canopy design?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- What is the thermal insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of the production process and workflow of carved aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-21 07:49:50

- Click:0

CarvingAluminum veneerAs a new type of building material, its manufacturing process and workflow are also very important. Let's analyze the production process and workflow of carved aluminum veneer below.

1、 Production process

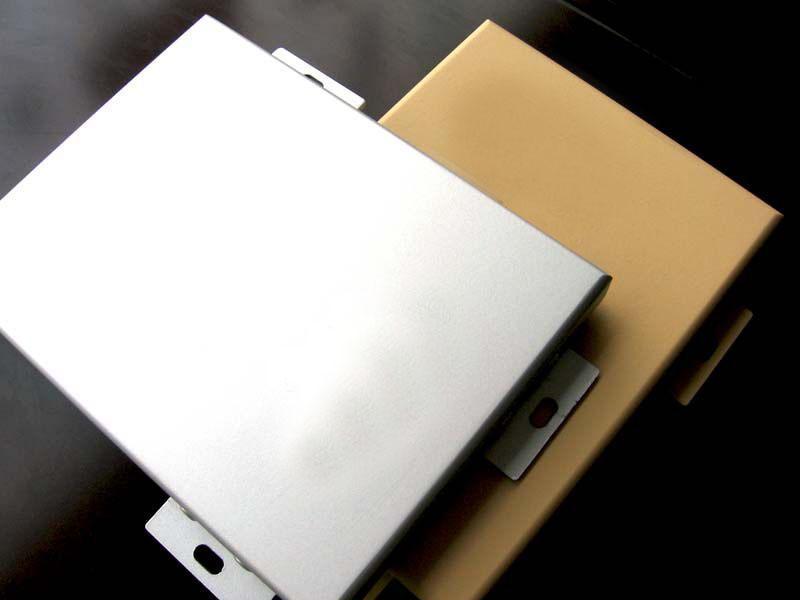

1. Raw material preparation: The raw materials for carved aluminum veneer mainly include aluminum alloy sheets, coatings, accessories, etc. Strict inspection and screening of raw materials are required to ensure product quality.

2. Cutting and processing: Cut and process aluminum alloy sheets according to design requirements to ensure accuracy in size and shape.

3. CNC punching: Using CNC punching machines to punch aluminum alloy sheets, forming the required patterns and holes.

4. Spray treatment: Spray the surface of aluminum alloy sheet to form the desired color and coating.

5. Assembly and installation: Assemble and install the punched and sprayed aluminum alloy sheet with other accessories to form a complete carved aluminum veneer.

2、 Process flow

1. Design phase: Based on customer needs and architectural design requirements, product design and scheme formulation are carried out.

2. Raw material procurement: Procure and inspect the required raw materials to ensure product quality.

3. Cutting and processing: Cutting and processing aluminum alloy sheets to ensure the accuracy of size and shape.

4. CNC punching: Using CNC punching machines to punch aluminum alloy sheets, forming the required patterns and holes.

5. Spray treatment: Spray the surface of aluminum alloy sheet to form the desired color and coating.

6. Assembly and installation: Assemble and install the punched and sprayed aluminum alloy sheet with other accessories to form a complete carved aluminum veneer.

7. Quality inspection: Conduct strict quality inspections on finished products to ensure that they meet design requirements and national standards.

3、 Conclusion

The production process and workflow of carved aluminum veneer are very complex, requiring multiple stages of processing and inspection to complete. In the future development, carved aluminum veneer will continue to strengthen technological innovation and quality assurance, improve production efficiency and product quality, and create a better living environment and social atmosphere for people.

Customer service QQ

Customer service QQ