Industry information

Company News

- Aluminum veneer: low-key building materials, high-end lifestyle

- Fluorocarbon aluminum veneer: a fashionable new favorite in the construction industry

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Curtain wall aluminum veneer: the "fashionable coat" of modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Customize aluminum veneer to create a unique spatial aesthetic

- The influence of aluminum veneer thickness on performance

- Aluminum veneer: a modern interpretation of architectural aesthetics

Frequently asked questions

- How does aluminum veneer affect indoor temperature?

- Is there a wide range of color options for aluminum veneer?

- Can aluminum veneer be used for building canopy design?

- What is the thermal expansion coefficient of aluminum veneer?

- Is the use of aluminum veneer limited by geographical environment?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

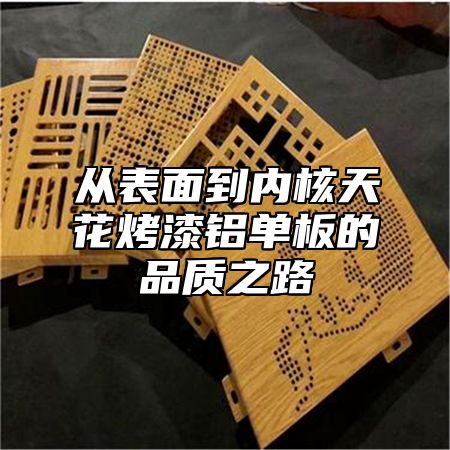

The quality path of painted aluminum veneer from surface to core ceiling

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-21 07:34:52

- Click:0

Ceiling baking paintAluminum veneerAs a new type of building material, it has the advantages of environmental protection, durability, and aesthetics. The path of its quality, from the surface to the core, requires strict control through multiple processes. The following will provide a detailed introduction.

1、 Raw material selection

The quality of ceiling painted aluminum veneer first depends on the selection of raw materials. High quality aluminum alloy materials are the foundation for producing high-quality ceiling painted aluminum veneers. Manufacturers need to conduct strict screening and testing of raw materials to ensure that they meet quality standards.

2、 Surface treatment

Surface treatment is a key step in ensuring the appearance of ceiling painted aluminum veneer. Firstly, it is necessary to polish and polish the aluminum alloy sheet to make its surface smooth and even. Then spray or roll coating treatment is carried out to form a uniform and dense coating on the surface, increasing its corrosion resistance and wear resistance. Finally, perform baking treatment to firmly adhere the coating to the surface of the aluminum alloy sheet.

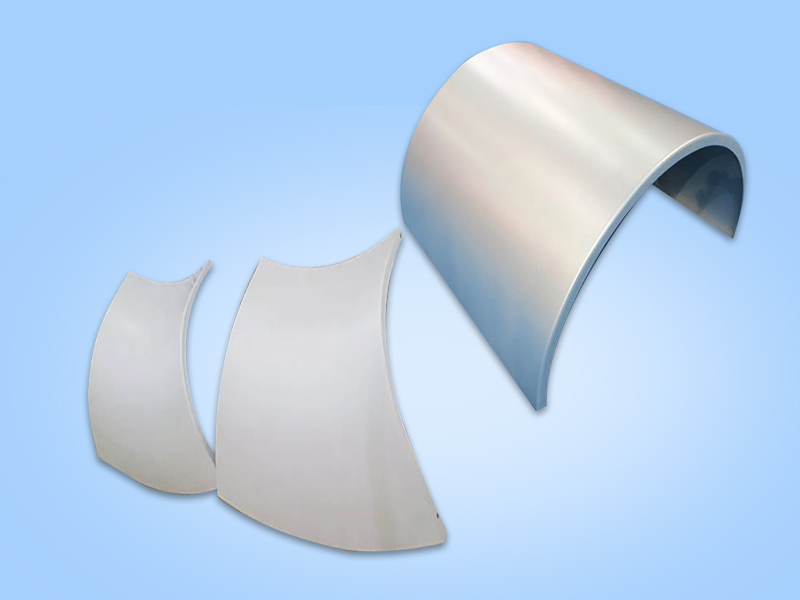

3、 Internal structural design

The internal structural design of the ceiling painted aluminum veneer is also an important factor in ensuring its quality. High quality ceiling painted aluminum veneer requires a reasonable internal structural design to enhance its load-bearing capacity and stability. It is also necessary to consider factors such as ventilation and sound insulation to improve its comfort and performance.

4、 Production process control

Production process control is another key link in ensuring the quality of ceiling painted aluminum veneer. Manufacturers need to establish a sound production process and quality management system, and strictly follow standard operating procedures for production. It is also necessary to monitor and detect key links in the production process to ensure that each process meets quality requirements.

5、 Quality inspection and certification

Ceiling painted aluminum veneer needs to undergo a series of quality inspections and certifications in order to be recognized as a qualified product. These tests include multiple indicators such as physical performance testing, chemical composition analysis, and appearance inspection. Only by passing these tests and obtaining corresponding certifications can it be proven that the product meets certain quality standards.

The quality path of ceiling painted aluminum veneer requires strict control of multiple processes, from raw material selection to production process control, and then to quality inspection and certification, each link requires excellence. Only in this way can high-quality ceiling painted aluminum veneer be produced, creating a better and healthier living environment for people.

Customer service QQ

Customer service QQ