Industry information

Company News

- Punched aluminum veneer: a fashionable choice for modern architecture

- Aluminum veneer: a light luxury choice for industrial aesthetics

- Fluorocarbon aluminum veneer: the new darling of modern architecture

- Aluminum veneer: an environmentally friendly and sustainable choice of building materials

- Aluminum veneer: understated luxury in modern architecture

Industry dynamics

- Analysis of Sound Insulation Effect of 1.5mm Aluminum Single Panel

- Durability and maintenance methods of aluminum veneer exterior wall decoration

- Fluorocarbon aluminum veneer: the 'invisible hero' in modern architecture

- Aluminum veneer: the "hidden master" in light luxury building materials

- Aluminum veneer: the beauty of lightness, a fashionable choice for modern architecture

Frequently asked questions

- Can aluminum veneer be used for building canopy design?

- Is there a wide range of color options for aluminum veneer?

- How sustainable is aluminum veneer?

- Can aluminum veneer be applied to the exterior design of sports buildings?

- What is the thermal expansion coefficient of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production and processing process of curtain wall aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 20, 2025 14:06:05

- Click:0

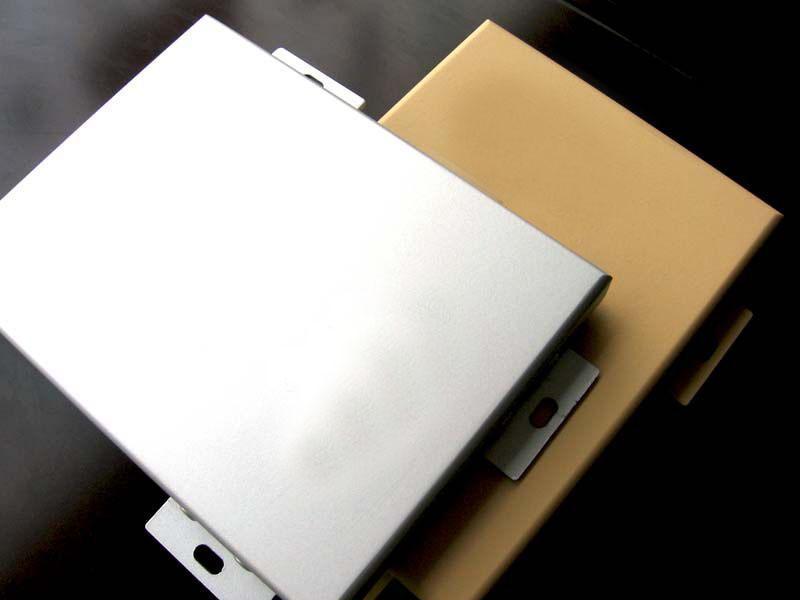

curtainAluminum veneerIt is a new type of building material that requires multiple processes in its production and processing. Let's take a look at the production and processing process of curtain wall aluminum veneer together.

The production of curtain wall aluminum veneer requires the selection of raw materials. Normally, the main raw materials for curtain wall aluminum panels include aluminum alloy sheets, fluorocarbon coatings, etc. When selecting raw materials, factors such as strength, corrosion resistance, and thermal insulation performance need to be considered to ensure the quality and performance of the curtain wall aluminum veneer.

The production of curtain wall aluminum veneer requires cutting and bending processing. In the process of cutting and bending, professional equipment and technology are required to ensure the accuracy and quality of cutting and bending. It is also necessary to perform surface treatment on the cut and bent aluminum veneer to improve its surface quality and aesthetics.

Thirdly, the production of aluminum veneer for curtain walls requires the spraying of fluorocarbon coatings. Fluorocarbon coating is one of the important components of curtain wall aluminum veneer, which has good weather resistance and anti-corrosion performance, and can effectively resist the erosion of natural environments such as acid rain and ultraviolet radiation. During the spraying process, it is necessary to control the pressure and distance of the spray gun to ensure the uniformity and coverage area of the coating.

The production of curtain wall aluminum veneer requires subsequent processing and packaging. In the subsequent processing, it is necessary to polish and polish the aluminum veneer of the curtain wall to improve its surface quality and aesthetics. It is also necessary to package and transport the aluminum veneer of the curtain wall to ensure its safety and stability.

The production and processing process of curtain wall aluminum veneer requires multiple steps, including material selection, cutting and bending processing, fluorocarbon coating spraying, subsequent processing and packaging. Only through strict production and processing processes can high-quality curtain wall aluminum veneer products be produced. With the continuous advancement of technology and the development of society, people have higher expectations and requirements for future architectural decoration. I believe that aluminum veneer for curtain walls will play a more important role in future architectural decoration!

Customer service QQ

Customer service QQ