Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

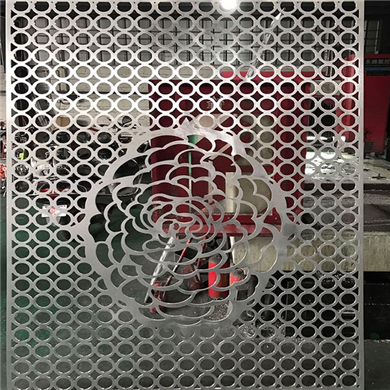

- The new favorite of light luxury, perforated aluminum veneer, is a fashionable tool for creative home decor!

- Unveiling Aluminum Veneers for Curtain Walls: The Fashionable Coat of Architecture

- Aluminum veneer: the new darling of industrial aesthetics, revealing its charm

- Aluminum veneer, the "light cavalry" of the construction industry

Industry dynamics

- Aluminum veneer customization: a unique interpretation of personalized space

- Unveiling the Aesthetics of Modern Architecture - The Charm of Curtain Wall Aluminum Veneers

- Aluminum veneer: the fashionable "coat" of industrial construction

- Aluminum veneer curtain wall: a perfect combination of architectural aesthetics and technology

- Unveiling the secret of curtain wall aluminum veneer: appearance and performance coexist!

Frequently asked questions

- How sustainable is aluminum veneer?

- Is the use of aluminum veneer limited by geographical environment?

- Can the insulation function of aluminum veneer be long-lasting and effective?

- How does aluminum veneer affect indoor temperature?

- Is there a wide range of color options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

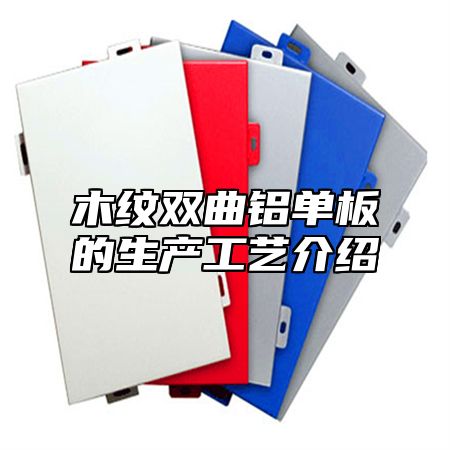

Introduction to the production process of wood grain hyperbolic aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 18, 2025 21:28:31

- Click:0

Wood grain hyperbolicAluminum veneerIt is a very popular decorative material, and its unique design style and good decorative effect are highly favored by people. Behind this excellent product, its exquisite production technology is indispensable. Next, we will provide a detailed introduction to the production process of wood grain hyperbolic aluminum veneer.

1、 Raw material preparation

Before producing wood grain hyperbolic aluminum veneer, strict screening and processing of raw materials are required. The commonly used raw materials include aluminum alloy sheets, coatings, polyester resins, etc. Aluminum alloy sheet is the main material for making wood grain hyperbolic aluminum veneer, with a thickness generally between 1.5mm-3mm.

2、 Cutting and processing

After the raw materials are prepared, they need to be cut and processed. Generally speaking, using CNC machining equipment for cutting can ensure the accuracy and quality of the product. After cutting, the aluminum material needs to be polished to remove burrs and uneven parts on the surface.

3、 Coating treatment

Coating treatment is a very important step in the production of wood grain hyperbolic aluminum veneer. The aluminum surface needs to be cleaned and degreased to ensure that the coating can firmly adhere to the surface. Polyester resin is sprayed or rolled onto the surface of aluminum to form a uniform coating. After the coating dries, it needs to be baked to make it harder and more durable.

4、 Wood grain printing treatment

In order to enhance the decorative effect of wood grain hyperbolic aluminum veneer, it is necessary to perform wood grain printing treatment on it. This step is usually completed by using special printing techniques to print wood grain patterns on polyester resin coatings. After printing treatment, the aluminum surface presents a natural wood grain texture, thereby enhancing the decorative effect and natural feeling of the entire building.

5、 Forming processing

After the wood grain printing process is completed, the aluminum material needs to be shaped and processed. Forming processing is usually carried out through mold extrusion, which involves placing aluminum material into a mold for extrusion molding. By extruding through molds, the surface of aluminum can be made to present a beautiful hyperbolic shape, thereby achieving the desired decorative effect.

6、 Subsequent processing

After the molding process is completed, it is necessary to perform subsequent processing on the wood grain hyperbolic aluminum veneer. This step usually includes inspection, packaging, and transportation. During the inspection process, it is necessary to conduct comprehensive quality inspection and testing on the product to ensure that it meets relevant standards and requirements. Corresponding measures need to be taken during packaging and transportation to protect the product from damage and contamination.

The production process of wood grain hyperbolic aluminum veneer is very complex, requiring the comprehensive application of multiple processes and technologies to complete a high-quality product. Manufacturers should strengthen technological innovation and management optimization, continuously improve product quality and technological level to meet market demand and customer expectations.

Customer service QQ

Customer service QQ